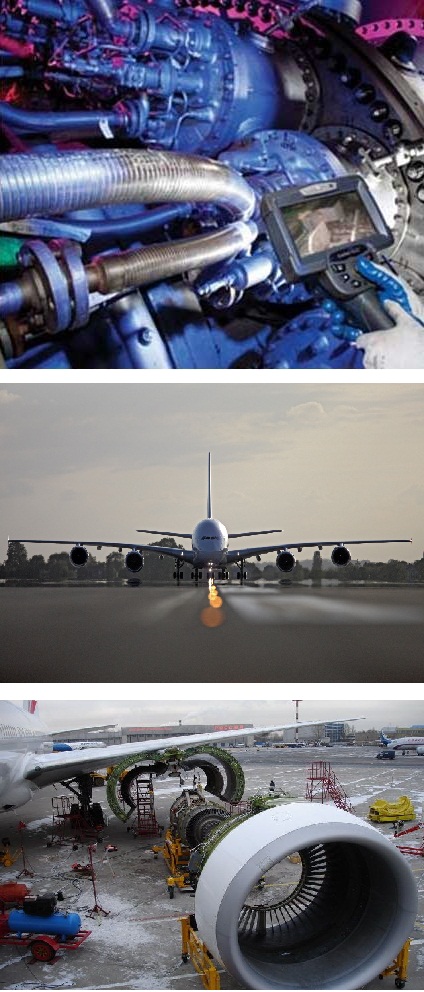

GACS provides professional aviation technical support services in the following areas:

Inspections -

- Aircraft factory in-production.

- Aircraft delivery/re-delivery.

- Aircraft/Engine lease in/lease return.

- Airport Apron/Runway.

- On site borescope.

Entry into service support -

- Aircraft acceptance.

- Line maintenance set up

- Start up spares, Ground support equipment and tools provisioning.

On site Representation -

- Aircraft/Engine/Component Manufacturer (OEM)

- Aircraft/Engine MRO Supplier.

Valuation -

- Aircraft (Used to buy or lease).

- Engine (Used to buy or lease).

Contract negotiations -

- Aircraft lease.

- Engine lease.

- Engine purchase.

- Aircraft purchase

Engine repair/refurbishment work scoping.

Invoice reconciliation -

- Engine repair/refurbishment against work scope.

- Aircraft major check against workpackage.

GACS provides professional services pertaining to legislation in the following areas:

- Assisting the industry to interpret and comply with ICAO Annexes, National primary legislation, Regulations and Requirements and Certification, Acceptance and Registration of new and used aircraft.

- Assisting and guiding Air Operators, Training Organisations and Maintenance Organisations establish systems approvable by their respective Authorities including the preparation of documents required for Certification and Approval.

- Guiding organizations to sustain Approvals by conducting continuous Audits on the Organisations, Aircraft Records, Spares Stock and Procurement Procedure, etc....

- To provide Oil Exploration Aviation support. Our capacity to perform quality/safety audits of air operations in Kenya and the region with a view to supporting the corporates such as the oil and gas companies when choosing providers of air services for their local travel.

- Guiding Operators to obtain and retain IOSA Certification.

Name - Naftaly Wanjohi Mwangi

Title - Aviation Consultant

Tel - +254 720 344095

email -

This email address is being protected from spambots. You need JavaScript enabled to view it.

Nationality – Kenyan

Address - P. O. BOX 54176-00200, Nairobi.

KEY QUALIFICATIONS

≥ B.Sc (Electrical Engg),Upper 2nd Class Hons (1975), University of Nairobi

≥ Engineering Internship at East African Airways (June 1975– Dec 1976)

≥ Aircraft Systems type courses at Airbus, Fokker and Boeing

≥ Manufacturer Systems courses for equipment fitted to various aircraft

≥ Various Senior Management Courses

≥ Emergency Response training (Blake)

≥ Job Evaluation course (Hay)

KEY ASSIGNMENTS

≥ Was accountable to the Technical Director for the Engineering Development, the Engineering Planning, the Aircraft Workshops and the Inventory Planning and Control divisions of the airline.

≥ Was responsible for Aircraft Base Maintenance and Aircraft Maintenance Planning divisions of the company.

≥ Sourced for suitable Maintenance Repair Organisations to undertake out-sourced maintenance of airframes, engines, landing gears, propellers and components and negotiated suitable contracts and oversaw their execution.

≥ Was a member and later the leader of the Airline’s aircraft Fleet Development team that determined the required fleet composition, developed aircraft specifications, requested and evaluated proposals, negotiated terms for the purchase or lease of additional aircraft, selected optional buyer furnished equipment, developed implementation budgets and oversaw the entire aircraft manufacturing, acceptance and entry into service processes.

≥ Was a member of the airline’s Job Evaluation team representing the Technical Department.

≥ Was a member of the airline’s Strategy Development team representing the Technical Department.

≥ Was the Crisis Management Centre (CMC) Technical Director where I represented the department and later assumed the role of its overall Director.

≥ Deputised for the airline’s Technical Director whenever he was away or the office was vacant.

≥ Was a member of the Committee of Experts appointed by the Kenya Government in August 2010 to study the structure, organization, fleets composition, facilities and equipment of public air wings and come up with recommendations on how they can be reformed.

KEY CAREER HISTORY

| Job Title | Date | Company |

| Head of Base Maintenance | 2006-2008 | Kenya Airways |

| Head of Technical Support | 1994-2006 | Kenya Airways |

| Manager Inventory Planning & Control | 1990-1994 | Kenya Airways |

| Manager Engineering Development | 1987-1990 | Kenya Airways |

| Senior Development Engineer | 1980-1987 | Kenya Airways |

| Development Engineer | 1977-1980 | Kenya Airways |

| Trainee Assistant Development Engineer | 1976-1977 | East African Airways |

Name - EPHANTUS KAMAU MBOGO

Title - Aviation Consultant

Tel - +254 733 201941

email -

This email address is being protected from spambots. You need JavaScript enabled to view it.

Nationality – Kenyan

Address - P. O. BOX 54176-00200, Nairobi.

KEY QUALIFICATIONS

≥ Diploma in Air transport Engineering - UK - 1975

≥ C&G Full Technological Certificate (F.T.C) “AET” “Operation Technology”. - 1985

≥ 4½ year Apprenticeship with EAA precursor to Kenya Airways. - 1971 to 1975

≥ Aeronautical Engineering Certificate (CAA-UK) - 1974

≥ KCAA AMEL cat. C rated for various engines. - 1979 forward.

≥ Attended aircraft and engine manufacturer’s maintenance courses on all fleet operated by Kenya Airways during my term there. (F27, B707, DC9, B737-300; 200, B767-300, F50, SAAB340, B737NG and B777-200).

≥ Attended various business development courses and seminars -

Aero-Engine Overhaul and Maintenance conferences.

General Electric Powerplant Engineering course.

Boeing Production Planning Requirements to Maintain Continued Airworthiness.

Aircraft Maintenance cost Seminar in Netherlands.

IATA International negotiation Skills.

KEY ASSIGNMENTS

≥ Over 40 years’ experience in Aircraft engineering and maintenance having started as an apprentice engineer and rising to Head of Aircraft Production at Kenya Airways.

≥ Production and inspection roles in line maintenance, hangar and workshops.

≥ Directly managed off-wing maintenance of all Kenya Airways’ fleet Propulsion Systems (Engines, APUs, Propellers, Thrust reversers, etc) for over 20 years by:

- Organising and guiding engine and propeller workshops production activities.

- Set up and managed a CF6-80C2 Engine Module change workshop at Kenya Airways.

- Forecasting and planning removals based on on-wing Performance and physical Condition Monitoring and established life limitations.

- Establishing off-wing workscopes and ensuring compliance with same at outsourced facilities.

- Ensuring Maintenance Release documents are complete and compliant with Airworthiness Regulations including EASA (JAR) and FAA.

≥ Was Head of Aircraft Production responsible to Technical Director for control and management of all maintenance and servicing activities at Line stations, Base and all workshops for 2½ years.

≥ Was Manager Technical Contracts at Kenya Airways for 2 years responsible for:

- Material supply and repair contracts.

- Warranty and manufacturers guarantee administration.

- Stock verification and audits.

≥ Retired from Kenya Airways in July 2011 as Propulsion Manager for 2½ years in charge of:

- Propulsion Systems management.

- Propulsion engineering.

- Propulsion leasing and Propulsion contracted maintenance administration.

≥ Has been trained in various management skills.

≥ Believes in being ethical and conscious to cost saving activities.

KEY CAREER HISTORY

| Job Title | Date | Company |

| Propulsion Manager | 2008 to 2011 | Kenya Airways |

| Manager Technical Contracts | 2006 to 2008 | Kenya Airways |

| Head of Aircraft Production | 2004 to 2006 | Kenya Airways |

| Manager Propulsion Systems | 1993 to 2003 | Kenya Airways |

| Head of Propulsion Support Group | 1990 to 1993 | Kenya Airways |

| Production Engineer - Engine Overhaul | 1988 to 1990 | Kenya Airways |

| Inspector - Engine Overhaul Shop | 1984 to 1988 | Kenya Airways |

| Engineering Supervisor – Line Maintenance | 1983 to 1984 | Kenya Airways |

| Licenced Aircraft Engineer - Line Maintenance | 1979 to 1983 | Kenya Airways |

| Technician – Engine Shop and Line Maintenance | 1975 to 1979 | East African/Kenya Airways |

| Apprentice Engineer | 1971 to 1975 | East African Airways |